Hydrogen energy is recognized as a clean energy source and is emerging as a low-carbon and zero-carbon energy source. Hydrogen is at the top of the periodic table, its atomic number is 1, it is gaseous under normal temperature and pressure, and it is liquid under ultra-low temperature and high pressure. Energy is the ultimate solution to the future human energy crisis.

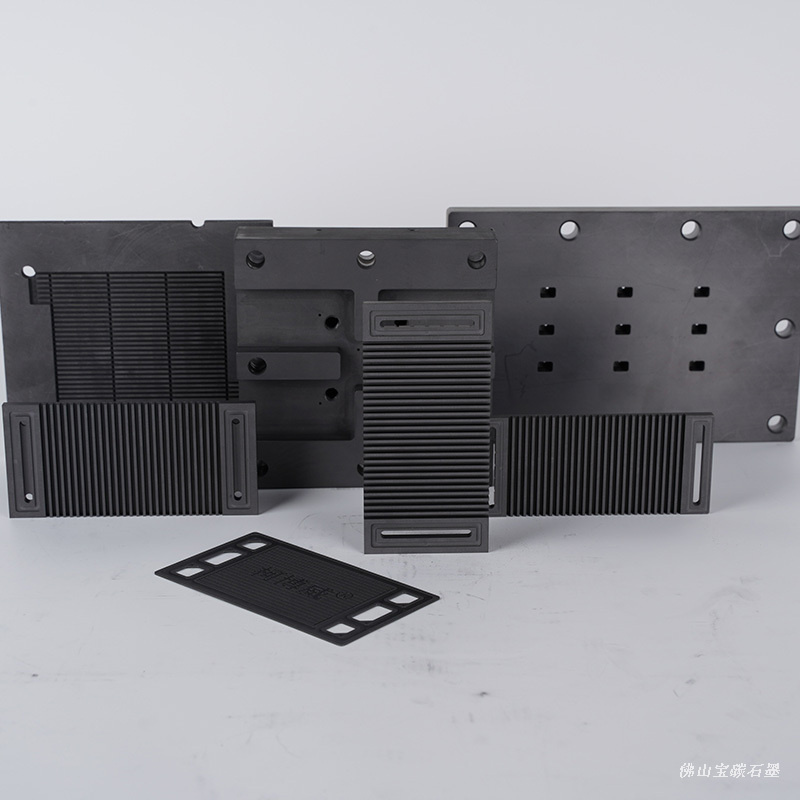

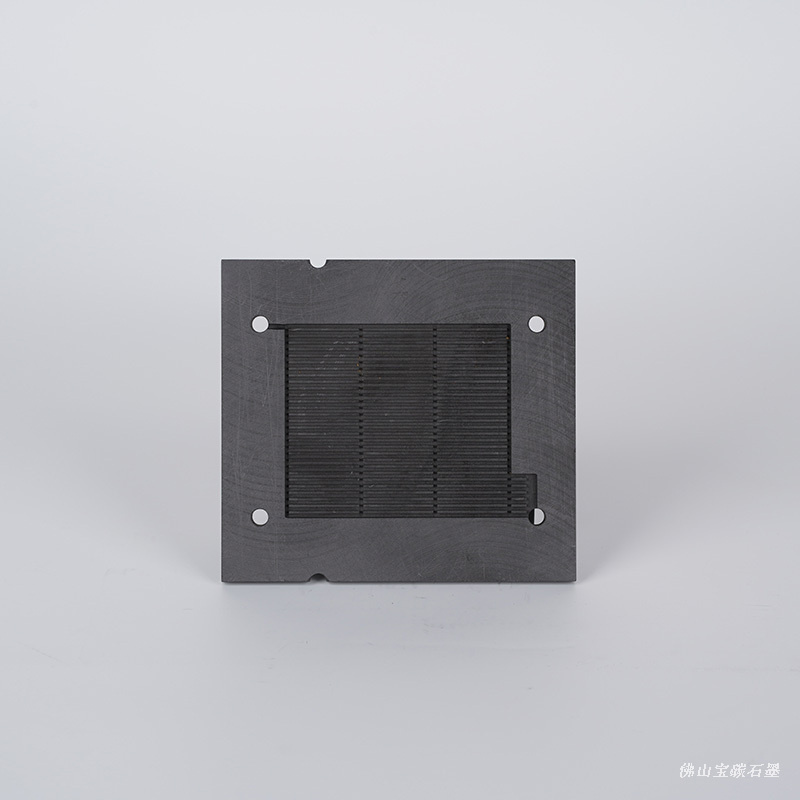

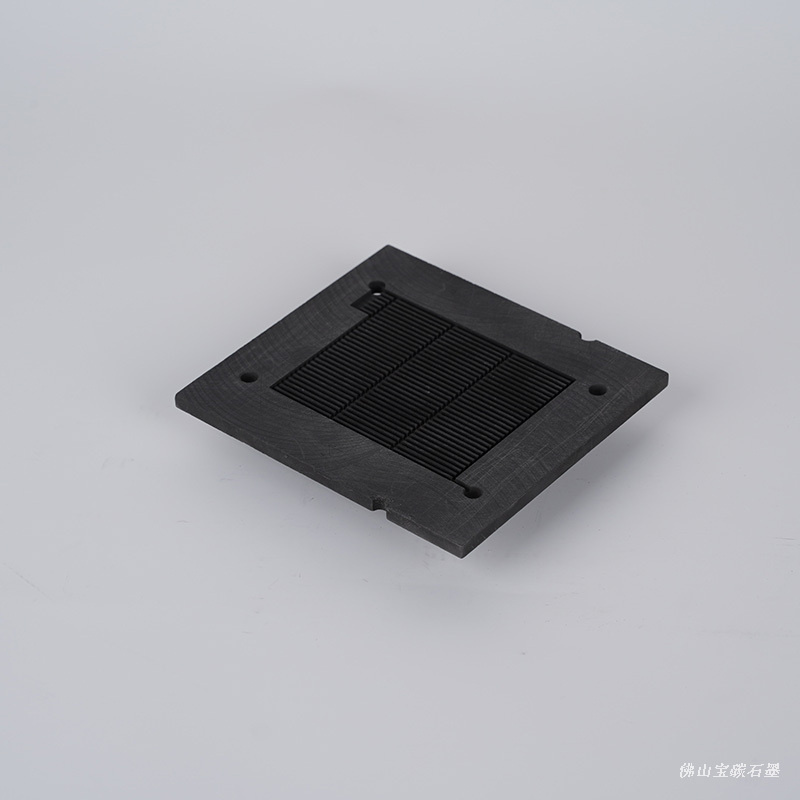

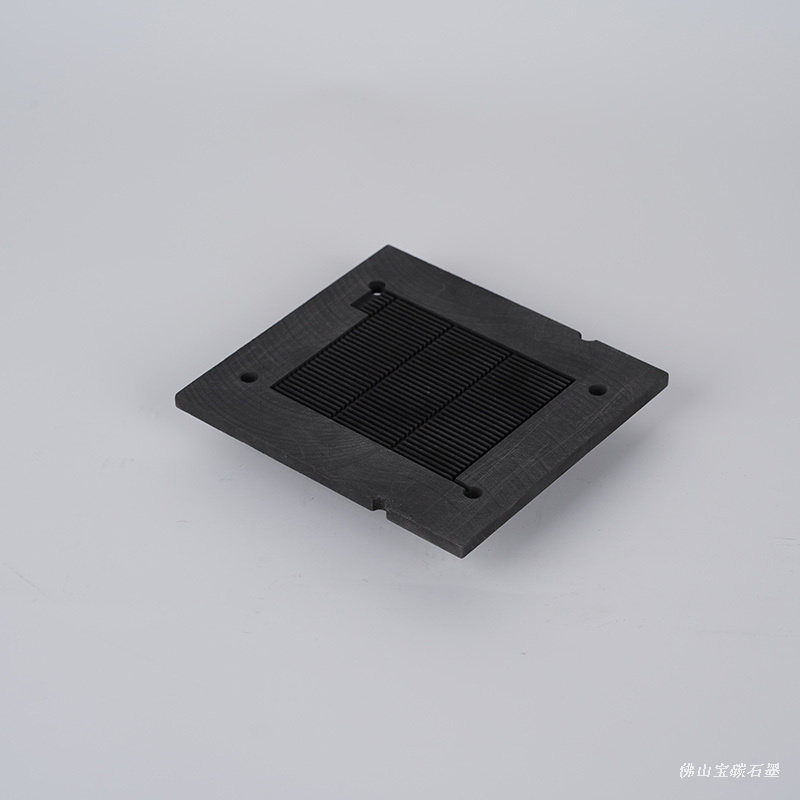

In the hydrogen power system, the stack is the core component, and the graphite bipolar plate is the core structural component of the stack, which plays the role of evenly distributing gas, draining water, conducting heat, and conducting electricity. Its performance directly affects the output power of the battery and service life.

A hydrogen fuel cell board typically refers to a specific component or assembly within a hydrogen fuel cell system.

Fuel Cell Stack: The primary component of a hydrogen fuel cell system is the fuel cell stack. A hydrogen fuel cell board could refer to a portion of or the entire stack, which consists of multiple individual fuel cells arranged in a series or parallel configuration.

Bipolar Plate Assembly: The bipolar plates within a fuel cell stack are typically made of materials like graphite or metal. A hydrogen fuel cell board could include the bipolar plates, gaskets, and other components that make up this critical part of the fuel cell.

Stack Board or Housing: In some fuel cell designs, there may be a board or housing that contains and supports the fuel cell stack. This stack board ensures proper alignment and distribution of reactants (hydrogen and oxygen) to the individual cells.

Electrical Connections: The board could also include electrical connections, such as busbars or conductive paths, that allow for the collection of electricity generated by the individual fuel cells within the stack.

Hydrogen and Oxygen Flow Channels: The board may have integrated channels or pathways for the controlled flow of hydrogen and oxygen gases to the individual cells within the stack. These channels are crucial for optimizing the electrochemical reactions.

Cooling and Thermal Management: Some fuel cell boards incorporate cooling systems to manage the temperature within the stack, ensuring optimal performance and longevity.

Control and Monitoring Electronics: In advanced fuel cell systems, the board may include control and monitoring electronics that regulate the flow of reactants, manage voltage and current, and collect data on the fuel cell's performance.

Fuel Cell System Integration: A hydrogen fuel cell board could also refer to an integrated component that includes not only the fuel cell stack but also associated components like fuel and air supply systems, humidification, and exhaust management.