Graphite rods, also known as carbon rods, are cylindrical structures made from high-purity graphite, a naturally occurring form of carbon. These versatile rods boast an array of exceptional properties, including high heat resistance, excellent electrical conductivity, and resistance to chemical corrosion, making them indispensable in numerous applications across diverse industries.

Some of the most prominent uses of graphite rods include moderating nuclear fission reactions in nuclear reactors, serving as conductive components in electrical equipment and batteries, acting as precision drawing tools for artists, facilitating electrolysis and chemical reactions, aiding in melting and casting metals in foundries, functioning as dry lubricants and heat exchangers, enabling electrical conductivity testing, providing thermal insulation and protective equipment, and even crafting lightweight and sensitive fishing rods.

Nuclear Reactors: Moderating Nuclear Fission

In the realm of nuclear power generation, graphite rods play a critical role as moderators to control the nuclear fission process. Within these reactors, graphite rods help slow down the fast-moving neutrons produced during fission reactions, increasing the likelihood of these neutrons interacting with the uranium fuel and inducing further fission reactions. This moderation process is crucial for maintaining a controlled and sustainable nuclear chain reaction, ensuring the safe and efficient operation of nuclear power plants worldwide.

Electrical Industry: Conductivity and Heat Resistance

The electrical industry heavily relies on graphite rods due to their exceptional electrical conductivity and resistance to high temperatures. These rods are commonly used as electrodes in electric arc furnaces for steel production, where they facilitate the flow of electricity and generate intense heat to melt and refine metals. Additionally, graphite rods find applications in batteries, serving as conductive components that enable the flow of electrons during chemical reactions.

Arts and Crafts: Precision Drawing Tools

In the creative realm of arts and crafts, graphite rods are widely recognized as the core component of pencils. The graphite core, encased in wood or other materials, allows artists to create precise lines and intricate shading in their drawings. The unique properties of graphite, such as its softness and ability to leave a dark mark on paper, make it an indispensable tool for artists and illustrators worldwide.

Chemical Industry: Electrolysis and Reactions

The chemical industry utilizes graphite rods in various processes, including electrolysis and chemical reactions. During electrolysis, graphite rods serve as electrodes, facilitating the flow of electricity and enabling chemical reactions to occur. Their resistance to corrosion and high temperatures makes them ideal for use in harsh chemical environments, ensuring reliable and efficient operations.

Foundry Industry: Melting and Casting Metals

In the foundry industry, graphite rods play a crucial role in melting and casting metals. They can act as heating elements or crucibles in furnaces, leveraging their exceptional heat resistance and non-reactivity to withstand the extreme temperatures required for melting and shaping metals. This application is particularly valuable in the production of cast iron, steel, and other metal alloys.

Lubricants and Heat Exchangers

Graphite's unique properties also make it suitable for use as a dry lubricant in various industrial applications. Its low friction coefficient and ability to withstand high temperatures make graphite rods an excellent choice for reducing wear and tear in machinery and equipment. Additionally, graphite rods are sometimes employed in heat exchangers due to their ability to withstand extreme temperatures while maintaining low thermal conductivity.

Electrical Conductivity Testing

In the field of electrical engineering, graphite rods are utilized in electrical conductivity testing. Their conductive nature allows them to be incorporated into circuits, enabling researchers and engineers to measure the conductivity of various materials accurately. This application is crucial in the development and testing of new materials for electrical applications.

Thermal Insulation and Protective Equipment

While graphite is an excellent conductor of electricity, it also exhibits low thermal conductivity, making it a suitable material for thermal insulation in certain applications. Graphite rods can be used as insulating components in high-temperature environments, protecting sensitive equipment or materials from excessive heat exposure. Additionally, graphite's non-reactivity and heat resistance make it a valuable material for protective equipment in hazardous environments.

Fishing Rods: Lightweight and Sensitive

In the world of fishing, graphite rods have become increasingly popular due to their lightweight and sensitive nature. Anglers appreciate the responsiveness of graphite rods, which allow them to detect even the slightest bites from fish, particularly in clear or shallow waters where fish are easily spooked. The low weight of graphite rods also reduces fatigue, enabling anglers to fish for extended periods without experiencing excessive strain.

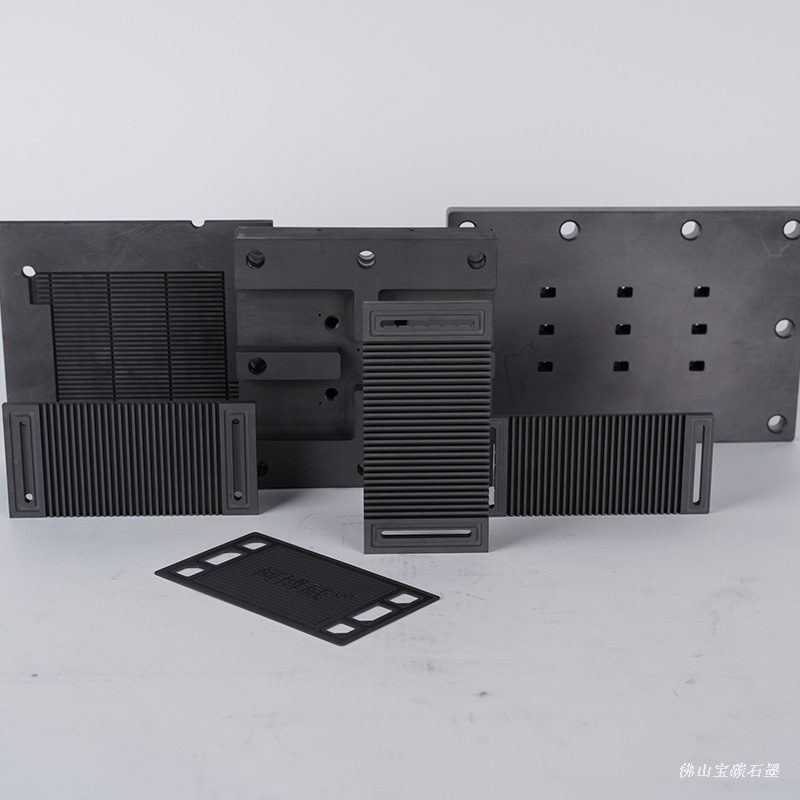

Manufacturing Process: From Raw Materials to Finished Products

The manufacturing process of graphite rods involves several intricate steps to ensure their high quality and consistent performance. The process begins with the preparation of raw materials, such as petroleum coke, needle coke, and coal tar pitch. These materials are ground, calcined, and mixed to form a homogeneous mixture.

The mixture is then formed into the desired shape using extrusion or molding techniques, after which it undergoes a baking process at high temperatures to carbonize the material. This step is followed by impregnation, where the porous carbon structure is filled with a liquid pitch to increase density and strength.

After another round of baking, the rods undergo graphitization, a process that involves heating them to temperatures exceeding 3000°C (5432°F) in an inert atmosphere. This step transforms the carbon structure into the highly ordered and crystalline form of graphite, imparting the desired properties to the rods.

Finally, the graphite rods undergo machining and inspection to ensure they meet the required specifications before being packaged and shipped to their respective industries.

Conclusion

Graphite rods are truly versatile materials that have found applications in a wide range of industries, from nuclear reactors and electrical equipment to artistic pursuits and fishing. Their unique combination of properties, including high heat resistance, excellent electrical conductivity, and resistance to chemical corrosion, make them invaluable in various processes and applications.

As technology continues to evolve, the demand for graphite rods is likely to increase, driving further advancements in their manufacturing processes and potential applications. By understanding the diverse uses of graphite rods, we can appreciate the vital role they play in our modern world and the ongoing efforts to harness their exceptional properties for the benefit of various industries and endeavors.

_853.jpg)

_867.jpg)