Graphite, a form of carbon known for its remarkable properties, is increasingly gaining prominence in the semiconductor industry as a vital material for various manufacturing processes. From thermal management solutions to precision machining applications, graphite materials are playing a crucial role in driving innovation and advancing semiconductor technology. In this article, we delve into the diverse range of graphite materials used in semiconductor manufacturing and their significance in shaping the future of electronic devices.

Graphite's Versatility in Semiconductor Manufacturing

Semiconductor manufacturing involves a myriad of complex processes, each requiring materials with specific properties to achieve optimal results. Graphite materials offer a unique combination of characteristics that make them well-suited for various semiconductor fabrication applications.

Some of the key graphite materials utilized in semiconductor manufacturing include:

1. Graphite Heat Spreaders and Thermal Interface Materials

One of the primary challenges in semiconductor devices is managing heat dissipation to ensure optimal performance and reliability. Graphite's exceptional thermal conductivity makes it an ideal choice for heat spreaders and thermal interface materials in semiconductor packages. By efficiently conducting heat away from sensitive components, graphite helps maintain stable operating temperatures and prolongs the lifespan of electronic devices.

2. Graphite Crucibles and Susceptors

In semiconductor crystal growth processes such as epitaxy, graphite crucibles, and susceptors play a crucial role in providing a controlled environment for the deposition of thin semiconductor films. Graphite's high thermal stability, chemical inertness, and compatibility with high vacuum conditions make it an excellent choice for these applications, ensuring the production of high-quality semiconductor materials with minimal contamination.

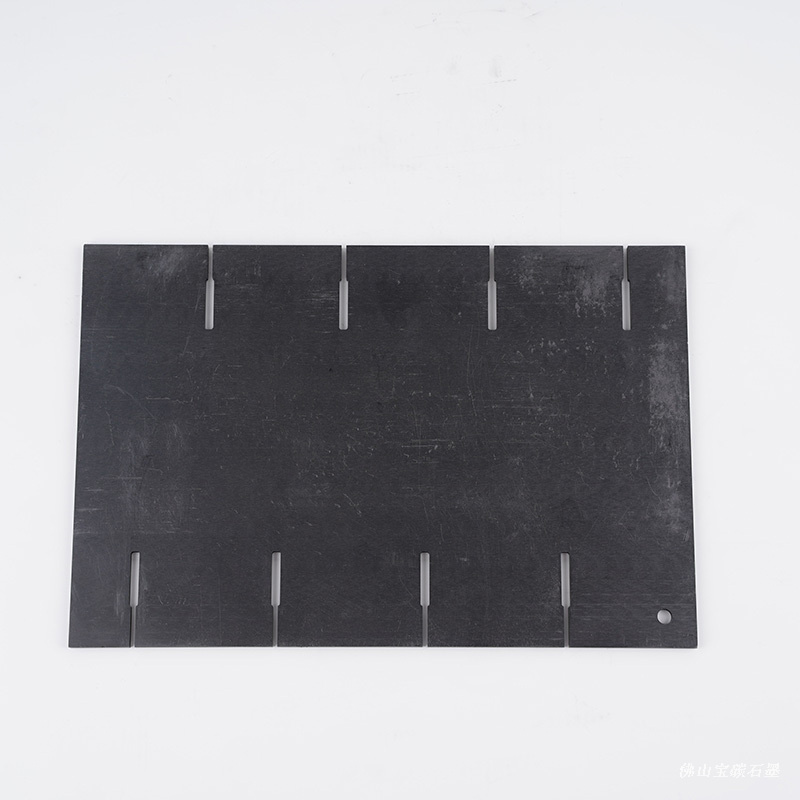

3. Graphite Electrodes for Plasma Etching and Ion Implantation

Graphite electrodes are widely used in semiconductor manufacturing equipment for processes such as plasma etching and ion implantation. Graphite's ability to withstand high temperatures and corrosive environments makes it an ideal electrode material for generating plasma and directing ion beams with precision. Its low sputtering rate and excellent electrical conductivity contribute to the efficiency and reliability of these semiconductor fabrication processes.

4. Graphene-Based Semiconductor Components

Graphene, a two-dimensional form of graphite, holds immense promise for next-generation semiconductor devices due to its exceptional electrical, thermal, and mechanical properties. Graphene-based transistors interconnects, and sensors are being explored for their potential to enhance device performance, reduce power consumption, and enable novel functionalities in electronic devices.

Advancing Semiconductor Technology with Graphite

The utilization of graphite materials in semiconductor manufacturing is driving significant advancements in device performance, reliability, and scalability. By leveraging the unique properties of graphite, semiconductor manufacturers can overcome technical challenges and push the boundaries of innovation in electronic device design and fabrication.

In conclusion, graphite materials play a critical role in semiconductor manufacturing, offering a versatile solution for various fabrication processes and device applications. From thermal management solutions to precision machining components, graphite materials contribute to the efficiency, reliability, and performance of semiconductor devices. As semiconductor technology continues to evolve, the demand for graphite materials is expected to grow, further solidifying their position as indispensable assets in the semiconductor industry's quest for continuous advancement and innovation.

_853.jpg)

_867.jpg)