As the world transitions towards clean and renewable energy sources, graphite materials have emerged as pivotal components in advancing hydrogen energy production, particularly in the context of hydrogen fuel cells.

These materials play a crucial role in enhancing the efficiency, durability, and overall performance of hydrogen fuel cells, notably in the form of graphite bipolar plates and hydrogen fuel cell boards.

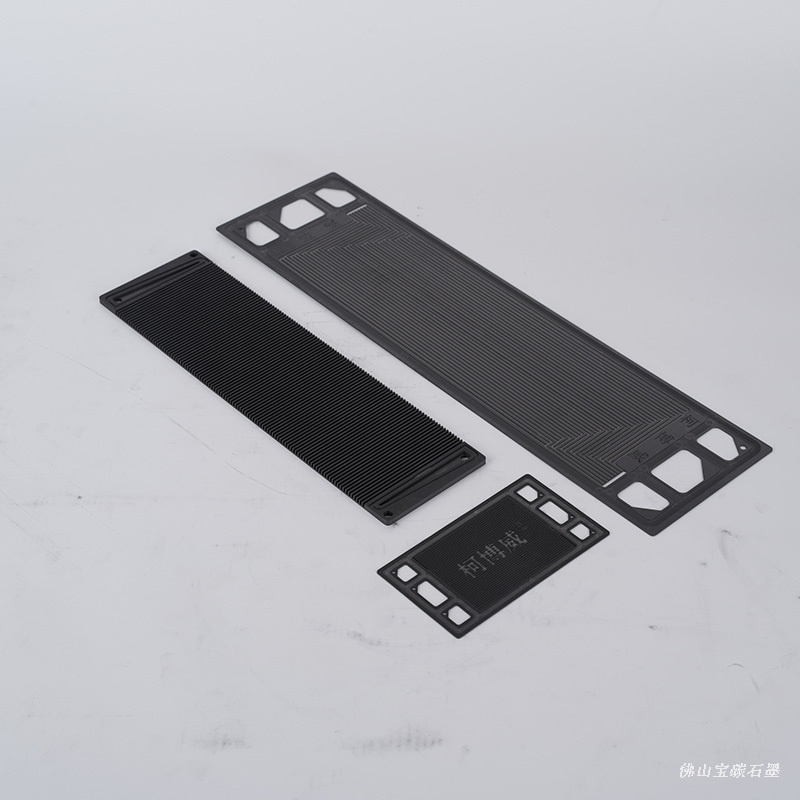

Graphite Bipolar Plates: Powerhouse of Hydrogen Fuel Cells

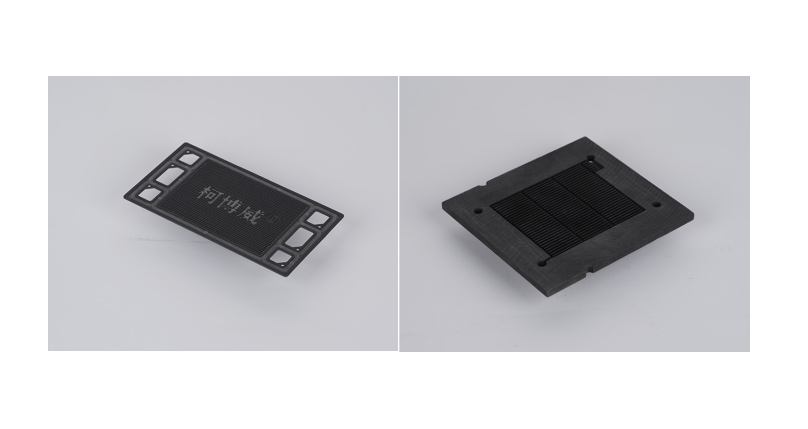

Graphite bipolar plates serve as crucial components in hydrogen fuel cells, facilitating the flow of hydrogen and oxygen while conducting electricity between cells.

The use of graphite in bipolar plates offers several advantages. Its lightweight nature, coupled with excellent electrical conductivity and corrosion resistance, makes it an ideal material choice.

These plates significantly contribute to the efficiency of fuel cells by enabling efficient electrochemical reactions, reducing energy loss, and maintaining structural integrity over extended usage.

Characteristics of Graphite Bipolar Plates

Conductivity: Graphite's exceptional electrical conductivity ensures efficient distribution of current within the fuel cell, enhancing overall performance.

Corrosion Resistance: Graphite's resistance to corrosion in harsh environments ensures the longevity and reliability of the bipolar plates, crucial for sustained fuel cell operation.

Mechanical Strength: The robustness and mechanical strength of graphite materials prevent deformation under pressure, maintaining the structural integrity of the fuel cell assembly.

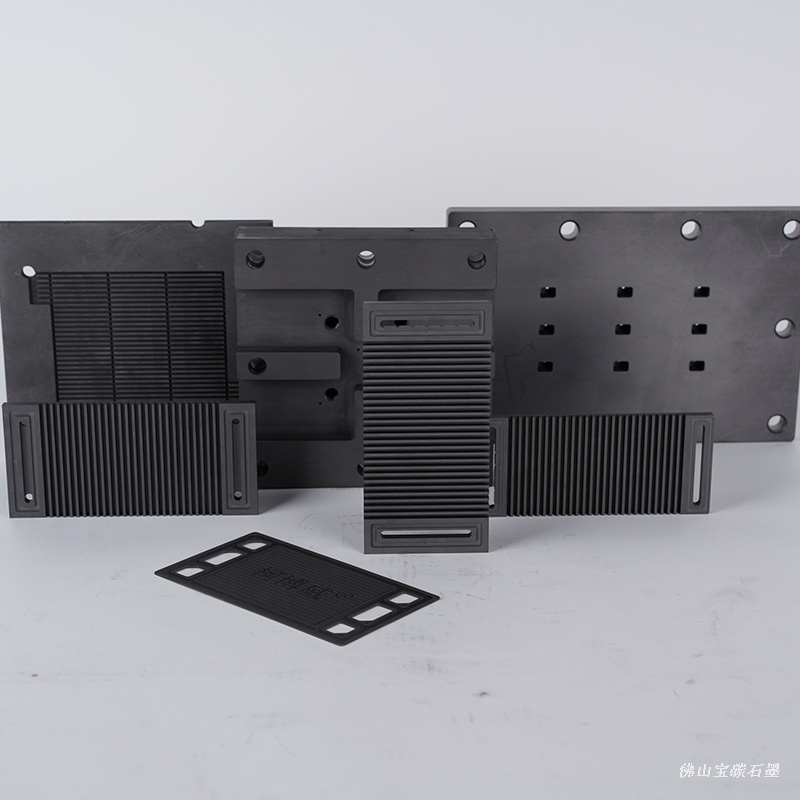

Advancements in Hydrogen Fuel Cell Boards

Hydrogen fuel cell boards, predominantly composed of graphite materials, serve as the core structural component within fuel cells, supporting the stack assembly and maintaining airtight compartments.

Ongoing research focuses on enhancing the properties of graphite-based fuel cell boards. Innovations include modifications in material composition and manufacturing processes to improve conductivity, durability, and cost-effectiveness.

Engineers continually refine the design of these boards to ensure improved gas diffusion, minimized electrical resistance, and efficient heat dissipation, optimizing overall fuel cell performance.

The Role of Hydrogen Fuel Cell Boards in Hydrogen Energy Production

Efficiency Improvement: The integration of graphite materials in hydrogen fuel cell technology contributes significantly to enhancing the efficiency of hydrogen energy production.

Environmental Impact: Hydrogen fuel cells powered by graphite components offer a clean energy alternative, producing only water as a byproduct, thus mitigating environmental concerns associated with conventional energy sources.

Industrial Applications: The adoption of these materials in fuel cells finds applications in various sectors, including automotive, aerospace, stationary power generation, and portable electronic devices, paving the way for a diversified use of hydrogen as an energy source.

In conclusion, graphite materials, particularly in the form of bipolar plates and fuel cell boards, stand as indispensable components in advancing the efficiency and viability of hydrogen fuel cells.

The graphite materials in the hydrogen energy production of Koboi stand as a testament to our unwavering commitment to quality. Crafted with precision using advanced materials, our hydrogen fuel graphite bipolar plates and hydrogen fuel cell boards exhibit exceptional durability, thermal stability, and corrosion resistance.

Embrace the future of clean energy with Koboi's hydrogen energy products. Dive into a world of efficiency, reliability, and environmental consciousness with our cell board and graphite bipolar plates in hydrogen fuel cells for clean energy. Please feel free to contact us to discuss specific details, pricing, and volume discounts.

_853.jpg)

_867.jpg)