Graphite, a versatile and high-performance material, plays a crucial role in the aerospace industry. Its unique properties, including exceptional thermal conductivity, high strength-to-weight ratio, and self-lubricating characteristics, make it an ideal choice for various aerospace applications. Here are the key ways in which graphite is used in the aerospace sector and how it contributes to the development of advanced aircraft and spacecraft.

Lightweight Structural Components

One of the primary advantages of graphite in aerospace is its ability to create lightweight structural parts. Graphite composites offer higher strength-to-weight ratios compared to traditional materials like metals and plastics. This enables the production of efficient designs that are both structurally sound and aerodynamically optimized. Leading aircraft manufacturers, such as Boeing and Airbus, are increasingly incorporating graphite composites into their aircraft to improve fuel efficiency and performance.

Thermal Management Systems

Graphite's excellent thermal conductivity makes it a valuable material for thermal management systems in aerospace applications. It is used in the construction of heat sinks and other components that help dissipate heat generated by electronic equipment and propulsion systems. By ensuring that critical systems operate within safe temperature limits, graphite helps maintain the reliability and safety of aircraft and spacecraft.

Electrical Discharge Machining (EDM) Electrodes

In the precision machining of aerospace components made from hard materials like titanium and nickel alloys, graphite electrodes are commonly used in electrical discharge machining (EDM) processes. The unique properties of graphite allow for the creation of complex shapes and features in these tough materials, enabling the production of high-quality aerospace parts.

Aviation Brake Systems

Graphite composites are also employed in aircraft brake systems due to their high thermal conductivity, low wear rates, and impressive strength. These materials can withstand the extreme temperatures and forces generated during aircraft landings, providing reliable and consistent braking performance. The use of graphite in brake systems contributes to the overall safety and efficiency of modern aircraft.

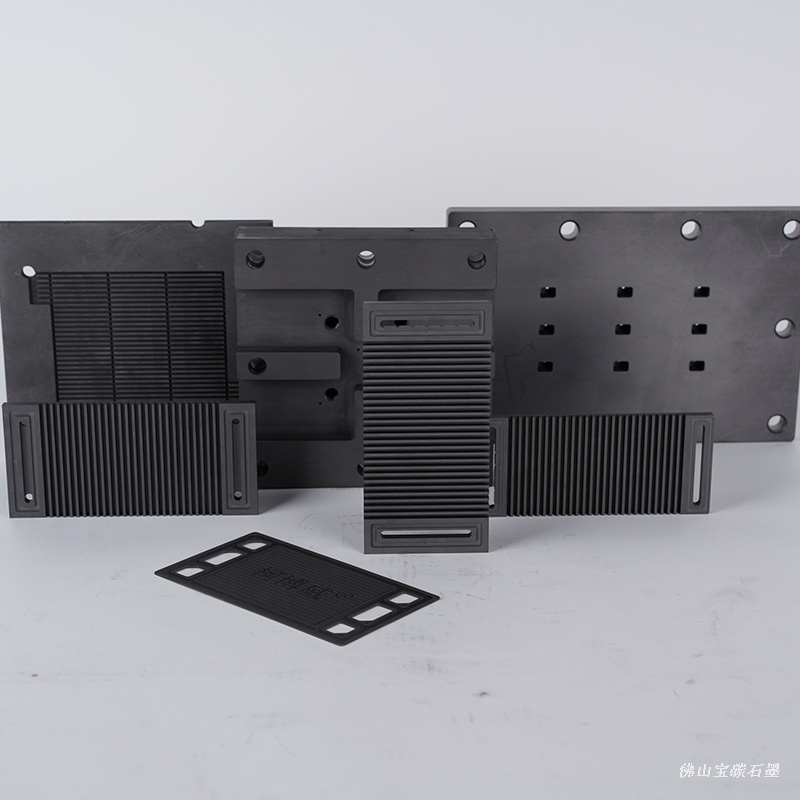

Fuel Cells and Propulsion Systems

As the aerospace industry explores alternative power sources, graphite is finding applications in fuel cell systems and advanced propulsion technologies. Graphite is used in the electrodes and bipolar plates of fuel cells, which generate electricity through electrochemical reactions. Additionally, graphite is utilized in ion thrusters, a type of electric propulsion system used in spacecraft for long-duration missions.

Spacecraft Components and Radiation Shielding

In the harsh environment of space, graphite's unique properties make it an essential material for various spacecraft components. It is used in satellite thermal shields, rocket nozzle throats, and payload structures. Graphite composites are also employed for radiation shielding to protect astronauts and sensitive equipment from the damaging effects of cosmic radiation.

Conclusion

Graphite's exceptional properties, including its lightweight nature, high thermal conductivity, self-lubricating characteristics, and mechanical strength, make it a vital material in the aerospace industry. From structural components and thermal management systems to precision machining and advanced propulsion technologies, graphite enables the development of cutting-edge aircraft and spacecraft.

Koboi Graphite is a leading provider of customized graphite solutions for the aerospace industry. With our expertise, advanced manufacturing processes, and commitment to quality, we are changing the way aerospace components are designed and produced. By partnering with Koboi Graphite, aerospace manufacturers can access the latest innovations in graphite technology and achieve unparalleled performance, efficiency, and safety in their products.

As the aerospace industry continues to push the boundaries of what is possible, graphite will undoubtedly remain a key material in driving innovation and performance. With Koboi Graphite's customized solutions, the future of aerospace is brighter than ever.

_853.jpg)

_867.jpg)