The cost of fuel cells has dropped significantly in recent years, but costs remain high and volumes remain low. Therefore, cost reduction is still the key to industrialization.

According to industry insiders, in the process of bipolar plates, membranes, catalysts and gas diffusion, the system cost of the fuel cell is about half, while the bipolar plate accounts for 80% of the weight of the entire fuel cell, and the cost is 24%. Therefore, it is very important to reduce the cost of bipolar plates.

Bipolar plates are mainly divided into graphite bipolar plates and metal bipolar plates. Currently, graphite sheets have an overall advantage. First of all, the current volume is not large enough to be mass-produced. In addition, graphite bipolar plates currently have a great advantage in service life. Graphite plates have been developed and produced for nearly half a century, and they have advantages in technology and technology. At present, graphite bipolar plates and sealing layers have been localized in China.

The energy chain understands that many domestic companies are supplying bipolar plates at present. On the technical route, they are also constantly developing and innovating, and they also plan to take the lead in the hydrogen energy outlet.

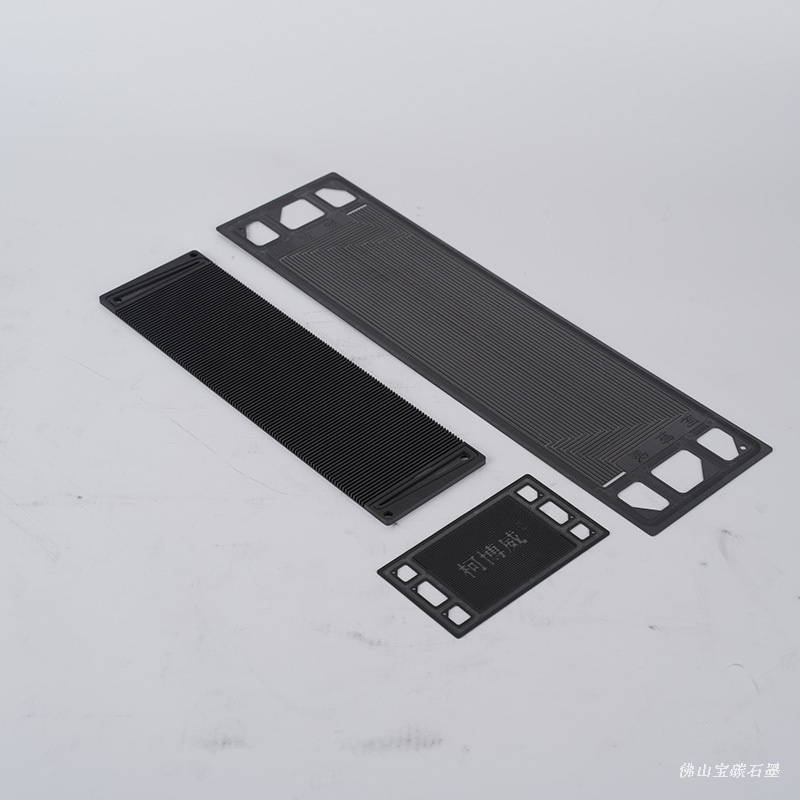

According to the workers, the fuel cell bipolar plates currently mainly use four materials: traditional artificial graphite bipolar plates, metal surface modified bipolar plates, composite bipolar plates, and flexible expanded graphite bipolar plates.

The metal bipolar plate has the advantages of convenient forming, light and thin plate, high volume power and weight power density. However, they face severe corrosion and contact problems in oxygen-containing environments. Surface modification can improve service life and increase cost.

Composite bipolar plates are easy to process and low in cost, but it is difficult to balance electrical conductivity and airtightness, so they have not been widely used so far.

Artificial graphite bipolar plate is a commonly used plate material. The production process is not difficult. It is processed and engraved with non-porous graphite. It has good electrical conductivity, thermal conductivity, corrosion resistance, and air tightness, but it takes a long time to process and mass production. low efficiency.

Flexible expanded graphite bipolar plate is an ideal bipolar plate material, which has been successfully applied in the fuel cell market. It is made of natural flake graphite through oxidation intercalation and high temperature expansion compression. It is easy to process, can be mass-produced, and has corrosion resistance. , good thermal conductivity, flame retardant, flame retardant and other characteristics.

In the product development stage, Carbon uses a variety of professional instruments to detect and control various physical and chemical indicators of graphite bipolar plates. In terms of size, it is equipped with a height instrument, a 2D image instrument and a fully automatic 3D inspection unit, especially the bipolar plate resistivity is leading, reaching ≤9μΩm.

It is worth noting that Shanghai Securities reported that the idea of subsidies related to fuel cells is not to supplement automakers as before, but to consider subsidizing manufacturers of core components, especially those with core technologies, which will receive more powerful Policy Support.

Therefore, bipolar plate companies that have mastered the core technology will surely win a place in the fuel cell industry.

_853.jpg)

_867.jpg)